Technological advances bring to market many new and often more environmentally friendly construction materials that become alternates to conventional products. If you didn’t think ‘concrete on a roll’ existed—guess again—it’s called Concrete Canvas®. Likewise, if you didn’t think there was anything other than steel/mesh for underground mining structural reinforcement, there is—enter Mine-Shield Grid™!

But what exactly are these innovations? Let’s explore.

Concrete Canvas® (CC), also known as ‘Concrete on a Roll’, is a revolutionary new class of construction material called Geosynthetic Cementitious Composite Mats (GCCMs). It consists of a three-dimensional geosynthetic fiber matrix filled with a high early strength cementitious powder mix that hardens on hydration to form a thin, durable, waterproof, and low-carbon concrete layer. Essentially, it is like concrete on a roll that allows for concrete construction, without the need for plant or mixing equipment.

Used for a wide range of erosion control applications, CC features numerous benefits that make it an attractive product. First, its low-mass, low-carbon technology uses up to 95 percent less material than conventional concrete for many applications. Second, CC’s roll format makes it logistically easier to handle and easier to install than conventional concrete—you just unroll, place and add water. Third, it can be installed very rapidly. In fact, CC can be laid at a rate of 200 square metres per hour—up to 10 times faster than conventional concrete solutions. Perhaps most impressive is that once hydrated, CC typically sets to 80 percent full strength within 24 hours. Once at full strength, its climatic resistance and durability can provide over 120 years of performance. Check out this engaging videocast interview with a Titan’s Concrete Canvas® Product Expert.

The combined benefits of CC make it an ideal product for mine channel and vent wall lining. It’s been was chosen for two large spillway erosion control lining projects recently completed at Eagle Gold Mine located in Northern Canada, approximately 200 kilometres from the Alaska Border, which sees seasonal variances of +20° C to -30° C.

The spillways are designed to convey any overtopped mine heap leachate in extreme weather conditions. They are likely to only experience flow in the case of a 200-year storm event. The main spillway (500 metres long) connects a heap leach pad to an events pond. The emergency spillway (140 metres long) is for the events pond. The mine site is heavily monitored by the Canadian mining regulator and Ministry of Mining.

Poured concrete with an applied coating was considered as the protective liner but discounted due to logistical and installation complexities. Concrete Canvas® alleviated these concerns and was chosen for the projects. A total of 8,240 square metres of CC8 and CC13 were installed. Installation was completed at a rate of 750 – 850 square metres per day at 15°C temperatures. This video case study gives an impressive view of this project.

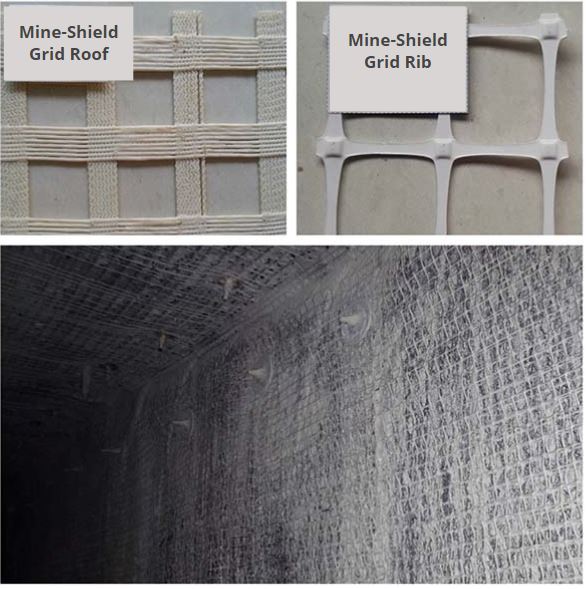

Moving on to Mine-Shield Grid™, another innovation in geosynthetics that is extending the lifecycle of critical mining infrastructure while helping to increase mine productivity rates, reduce maintenance costs, and improve underground mine-safety. Manufactured and supplied by Canadian-owned and operated Titan Environmental Containment, this cutting-edge technology has been widely adopted and used at mines in Australia, New Zealand, and South America, but it still new to the Canadian Mining sector.

What makes Mine-Shield Grid™ unique, you ask?

For starters, Mine-Shield Grid™ is an advanced line of high-strength polymer biaxial geogrid. It is designed as a load bearing alternative to steel/metal mesh for soft and hard rock underground mine applications, specifically mine tunnel roof and rib reinforcement.

Being a polymer product, not only is Mine-Shield Grid™ lighter than conventional steel and metal mesh, making it easier and faster to install, but it also does not rust or corrode and provides more than double the performance life (120-years versus 50-years). And unlike steel/metal mesh, Mine-Shield Grid™ can also be reused, minimizing environmental impact.

From a costing perspective, this product is proven to be 25 per cent more cost-effective than steel/metal mesh, and from a safety standpoint it is also far superior. Firstly, the fact that Mine-Shield Grid™ is lighter and blunter than steel/metal mesh reduces risk of injury during handling. Secondly, its design offers greater area surface coverage which significantly reduces the occurrence of rock fall-through when compared to conventional steel meshes. Lastly, its flame retardant additives and anti-static coating help to further reduce risk of injury from electric shock.

This short videocast interview with Titan’s Chief Technical Officer and designer of Mine-Shield Grid™ tells a great story on this product.

Titan Environmental Containment specializes in the supply and installation of high quality geosynthetics such as geomembrane liners, geogrids, geotextile fabrics, containment systems, erosion control products; and specialty civil engineering products that help manage and protect the environment and prolong the life of critical infrastructure in a range of sectors. We are proud to be an exclusive distributor of Concrete Canvas® and Mine-Shield Grid™.

Check out Titan Mining Infrastructure Solutions, including a collection of project case studies, or reach out to us here with product questions. Our team is always happy to help!